持續創新改善 全員追求卓越

Continuous innovation and improvement

All employees pursue excellence

Risk Management

Risk Management Policy

LASER TEK through systematic and institutionalized management systems to effectively identify, prevent and control risks to maintain operations

and achieve sustainable operations of the company.

To strengthen corporate governance and improve risk management functions for the purpose of sustainable operation, Laser Tek has formulated the 'Risk Management Policy and Operating Procedure.' Through systematic and institutionalized management, the company effectively identifies, prevents, and controls risks to maintain normal operations and achieve sustainable development. The company regularly inventories potential risks each year and further plans response measures to minimize risks and impacts. To establish risk awareness among all employees, risk management education and training or briefings are also held from time to time to promote the company's risk management policy, procedures, and requirements, thereby enhancing risk management awareness and execution. In addition, the company regularly prepares risk reports for submission to the board of directors and management, and keeps them on file for reference. In addition to disclosing relevant information as required by the competent authorities, risk management information is also disclosed on the company website and in the annual report.

Operational Risk Management

| Department | Duty |

|---|---|

| Board of Directors | The highest decision-making unit for risk management, responsible for approving risk management policies and frameworks, and supervising the effective operation of risk management mechanisms. |

| Risk Management Department | The authority responsible for implementing risk management. The department head is appointed by the chairman and currently consists of the highest supervisors of each business unit/functional organization. Responsible for coordinating relevant departments to identify, assess, control, and supervise risks, and regularly report implementation to the board of directors. |

| Relevant Departments | Each relevant department of the company assesses the likelihood and impact of various risk factors according to their responsibilities, formulates necessary measures and implements them, and properly manages various risks. |

Risk Management Process

| Risk Identification | Use feasible analysis tools and methods, summarize past experience and predict possible risks as a reference for subsequent measurement, monitoring, and management. Currently, the risk management department distributes risk identification questionnaires to mid- and senior-level managers to summarize the risks the company may face. |

|---|---|

| Risk Assessment | Risk management should measure different types of risks using quantitative or other feasible qualitative methods. |

| Risk Response | Considering risk tolerance and cost-effectiveness, select appropriate risk control mechanisms. |

| Risk Monitoring | Department heads should monitor and control the implementation of risk management within their scope of responsibility at all times and take necessary measures as appropriate. |

Risk Identification Results

| Rank | Risk Category | Risk Type | |

|---|---|---|---|

| 1 | Strategic | Industry development and market changes | Medium-High |

| 2 | Strategic | Procurement concentration - raw materials | Medium |

| 3 | Strategic | Technology R&D | Medium |

| 4 | Operational | Information security | Medium |

| 5 | Operational | Procurement concentration (raw materials/equipment) | Medium |

| 6 | Operational | Supply chain management | Medium |

| 7 | Financial | Interest/Exchange rate fluctuations and inflation | Medium |

| 8 | Operational | R&D projects and investment costs | Medium |

| 9 | Operational | Talent recruitment and retention | Medium |

| 10 | Financial | High-risk/high-leverage financial investment | Medium |

| 11 | Operational | Business continuity risk | Medium |

| 12 | Strategic | Strategic investment | Medium |

| 13 | Disaster prevention | Natural disasters | Medium |

| 14 | Operational | Economic, environmental, and social regulatory compliance | Medium-Low |

| 15 | Financial | Financing | Medium-Low |

| 16 | Disaster prevention | Fire and man-made disasters | Medium-Low |

| 17 | Disaster prevention | Occupational health and safety | Low |

Risk Matrix Diagram

Top Six Risks Description and Response

| Strategic Risks | ||

|---|---|---|

| Emerging Risk | Description | Response |

| Industry Development and Market Changes |

|

|

| Technological Innovation |

|

|

| Price Decline/Increase |

|

|

| Operational Risks | ||

| Emerging Risk | Description | Response |

| Information Security |

|

|

| Procurement Concentration (Raw Materials/Equipment) |

|

|

| Supply Chain Management |

|

|

Climate Change Response

In 2015, about 200 countries around the world jointly signed the Paris Agreement, aiming to reduce global greenhouse gas emissions and keep the global temperature rise this century well below 2°C above pre-industrial levels, and preferably limit it to 1.5°C. However, according to the latest United Nations Global Stocktake report, the temperature has already risen by 1.2°C. If the world does not take proactive actions, multiple tipping points may be triggered, leading to catastrophic disasters. Climate change has already brought about systemic changes, making it difficult for companies to predict future risks and opportunities. Therefore, the Task Force on Climate-related Financial Disclosures (TCFD) was developed to help companies and stakeholders focus on, reference, and assess related issues. Since 2020, Laser Tek has followed the TCFD framework to identify potential risks and opportunities. The company continues to improve relevant systems, hoping to use the TCFD framework to grasp the possible short-, medium-, and long-term impacts and shocks the company may face, enabling effective capital allocation and decision-making. This not only ensures the company's sustainable development but also helps slow down global warming and climate change.

Governance

Laser Tek's overall risk management is handled by the risk management department. To comprehensively incorporate risks from all aspects, climate change-related risks are included in the overall risk management process and assessed using the Task Force on Climate-related Financial Disclosures (TCFD) framework. The risk management department is responsible for identifying climate risks and opportunities and assessing their potential impact on company operations. The department is composed of the highest supervisors of each business unit/functional organization and works together with the Sustainability Committee Executive Office to collect data, formulate preventive and mitigation measures for climate risks, and enhance the effectiveness of climate risk response. The assessment results are reported to the board of directors at least once a year.

Responsibilities of LaserTek Climate-Related Issues Organization

| Unit | Responsibilities |

|---|---|

| Board of Directors | The highest decision-making unit for risk management, responsible for approving risk management policies and frameworks, and supervising the effective operation of risk management mechanisms. Since climate change issues have been incorporated into risk management, the implementation results are regularly reported to the board to ensure the effective implementation of climate-related risk management systems. |

| Risk Management Department | Composed of the highest supervisors of each business unit/functional organization, responsible for identifying risks and opportunities and assessing their impact on company operations. Hold meetings to discuss climate change and related topics, collect management's responses to climate change, consolidate company strategies, and submit climate risk management reports to the board. |

| Sustainable Development Committee Executive Office | Conduct climate scenario analysis, collect climate-related risks and opportunities, analyze evaluation forms from risk management department members, consolidate potential and actual risks and opportunities for the company, and plan related action or preventive/mitigation measures to produce climate risk management reports. |

Strategy

LaserTek identifies climate-related risks and opportunities by analyzing the latest domestic and international regulations and climate scenarios, identifying risk and opportunity factors that affect Laser Tek's operations, business, and finance, and compiling response measures for these factors, planning adaptation, mitigation plans, or implementing preventive measures. Laser Tek analyzes potential risks and opportunities through a risk matrix diagram, using impact level (financial impact) and likelihood (financial impact) as criteria, and evaluates whether each factor belongs to short-term (0-5 years), medium-term (5-10 years), or long-term (over 10 years) impact and the degree of financial impact. Based on the results of risk and opportunity analysis, relevant response plans and preventive measures are formulated.

Climate-Related Risks and Opportunities Matrix Diagram

Climate-Related Financial Impacts

| Category | Risk/Opportunity Factor | Financial Impact | ||||

|---|---|---|---|---|---|---|

| Asset Impairment | Financing Difficulty | Revenue Decrease | Cost Increase | Revenue Increase | ||

| Short-term | Total Greenhouse Gas Emissions Control | ✔ | ✔ | |||

| Require transparent disclosure of emission information | ✔ | |||||

| Increased customer environmental requirements | ✔ | ✔ | ||||

| Increase in raw material and energy costs | ✔ | |||||

| Reduced willingness of financial institutions to provide financing, investment, and insurance | ✔ | |||||

| Increased frequency and severity of extreme weather events | ✔ | ✔ | ||||

| Rising average temperature | ✔ | ✔ | ||||

| Low-carbon transport | ✔ | |||||

| Improve energy efficiency in plants | ✔ | |||||

| Obtain government subsidies and cooperation | ✔ | ✔ | ||||

| Participation in renewable energy projects | ✔ | |||||

| Improve product performance | ✔ | ✔ | ||||

| Mid-term | Carbon fee and carbon tax related regulations | ✔ | ||||

| Products and services replaced by low-carbon products and services | ✔ | |||||

| Low-carbon product and technology development | ✔ | |||||

| Customers change supplier selection criteria | ✔ | ✔ | ||||

| Corporate image impact | ✔ | ✔ | ||||

| Industry stigmatization | ✔ | ✔ | ||||

| Development and/or expansion of low emission goods and services | ✔ | ✔ | ||||

| Long-term | Sea level rise | ✔ | ✔ | |||

Climate-Related Risk Identification

| No. | Category | Risk Type | Climate-Related Risk | Risk Level |

|---|---|---|---|---|

| 1 | Transition | Policy and Regulation | Carbon fee and carbon tax related regulations | Medium-High |

| 2 | Transition | Market | Increase in raw material and energy costs | Medium |

| 3 | Transition | Market | Customers change supplier selection criteria | Medium |

| 4 | Transition | Technology | Products and services replaced by low-carbon goods | Medium |

| 5 | Transition | Technology | Low-carbon product and technology development | Medium |

| 6 | Transition | Market | Increased customer environmental requirements | Medium |

| 7 | Transition | Policy and Regulation | Renewable energy related regulations | Medium-Low |

| 8 | Physical | Long-term | Rising average temperature | Medium-Low |

| 9 | Physical | Immediate | Increased frequency and severity of extreme weather events | Medium-Low |

| 10 | Transition | Policy and Regulation | Require transparent disclosure of emission information | Medium-Low |

| 11 | Transition | Market | Reduced willingness of financial institutions to provide financing, investment, and insurance | Medium-Low |

| 12 | Transition | Long-term | Sea level rise | Medium-Low |

| 13 | Transition | Reputation | Corporate image impact | Low |

| 14 | Transition | Reputation | Industry stigmatization | Low |

Climate-Related Risk Response Measures

| Type | Category | Risk | Impact Timeline | Risk Description and Financial Impact | Response Measures/Action Plan |

|---|---|---|---|---|---|

| Transition | Policy and Regulation | Renewable energy-related regulations | Short (0–5 years) |

|

|

| Requirement for transparent disclosure of emission information | Short (0–5 years) |

|

|

||

| Carbon fee and carbon tax related regulations | Mid (6–10 years) |

|

|

||

| Technology | Products and services replaced by low-carbon goods | Mid (6–10 years) |

|

|

|

| Low-carbon product and technology development | Mid (6–10 years) |

|

|

||

| Market | Increased customer environmental requirements | Short (0–5 years) |

|

|

|

| Increase in raw material and energy costs | Short (0–5 years) |

|

|

||

| Reduced willingness of financial institutions to provide financing, investment, and insurance | Short (0–5 years) |

|

|

||

| Customers change supplier selection criteria | Mid (6–10 years) |

|

|

||

| Reputation | Corporate image impact | Mid (6–10 years) |

|

|

|

| Industry stigmatization | Mid (6–10 years) |

|

|

||

| Physical | Immediate | Increased frequency and severity of extreme weather events | Short (0–5 years) |

|

|

| Long-term | Rising average temperature | Short (0–5 years) |

|

|

|

| Sea level rise | Long (over 10 years) |

|

|

Climate-Related Opportunity Identification

| No. | Opportunity Type | Climate-Related Opportunity | Opportunity Level |

|---|---|---|---|

| 1 | Energy Source | Participation in renewable energy projects | Medium |

| 2 | Resource Use Efficiency | Low-carbon transport | Medium |

| 3 | Products and Services | Development of low-carbon goods and services | Medium |

| 4 | Resource Use Efficiency | Improve energy efficiency in plants | Medium |

| 5 | Products and Services | Improve product performance | Medium |

| 6 | Resource Use Efficiency | Obtain government subsidies and cooperation | Medium-Low |

Climate-Related Opportunity Response Measures

| Category | Opportunity | Impact Timeline | Opportunity Description and Financial Impact | Response Measures/Action Plan |

|---|---|---|---|---|

| Resource Use Efficiency | Low-carbon transport | Short (0–5 years) |

|

|

| Improve plant energy efficiency | Short (0–5 years) |

|

|

|

| Obtain government subsidies and cooperation | Short (0–5 years) |

|

|

|

| Energy Source | Participation in renewable energy projects | Short (0–5 years) |

|

|

| Products and Services | Improve product performance | Short (0–5 years) |

|

|

| Development and/or expansion of low-carbon goods and services | Mid (6–10 years) |

|

|

Climate Scenario Analysis

Laser Tek conducts scenario analysis of physical risks using the 'Taiwan Climate Change Projection Information and Adaptation Knowledge Platform Project' (TCCIP) and the '2024 County and City Climate Change Overview' published in cooperation with the Central Weather Administration, Ministry of Transportation and Communications, to estimate future changes in annual average temperature, number of days with high temperatures above 36°C, annual rainfall, and the longest consecutive dry days under different global warming scenarios (including 1.5°C and 2°C). The 'Climate Change Disaster Risk Adaptation Platform' (Dr.A) is also used to assess flood disaster risks under 1.5°C and 2°C warming scenarios, and the IPCC AR6 global sea level rise prediction tool is used to analyze sea level rise under 1.5°C and 2°C warming and SSP emission scenarios (including SSP1-2.6 and SSP5-8.5). For transition risk scenario analysis, Laser Tek adopts the International Energy Agency (IEA) 'Net Zero Roadmap: A Global Pathway to Keep the 1.5°C Goal in Reach,' the Science Based Targets initiative (SBTi), and Taiwan's Nationally Determined Contributions (NDCs Taiwan) for assessment.

Physical Risks

| Temperature | Baseline (1995-2014) | Global Warming Level (GWL) | |

|---|---|---|---|

| 1.5℃ | 2℃ | ||

| Annual Average Temperature | 19.7℃ | +0.7℃ | +1.1℃ |

| Number of Days with High Temperature ≥36℃ | 4.0 days | +7.2 days | +16.0 days |

| Laser Tek Response | |||

| Based on future projections (2015~2100) for Kaohsiung City, where the headquarters is located, under both 1.5℃ and 2℃ global warming scenarios, the annual average temperature in Kaohsiung will rise and the number of days with high temperatures above 36℃ will increase. The company must inventory existing facilities to ensure that equipment can continue to operate under future temperature increases without affecting business operations, or improve the working environment to adapt to consecutive hot days, providing a suitable workplace and complying with relevant regulations. This may require plant renovations, resulting in higher electricity costs, human resources, and asset burdens, and will increase the company's financial costs to a certain extent. | |||

| Precipitation | Baseline (1995-2014) | Global Warming Level (GWL) | |

|---|---|---|---|

| 1.5℃ | 2℃ | ||

| Annual Precipitation | 2,322.9 mm | +1.5% | +2.4% |

| Longest Consecutive Dry Days per Year | 49.0 days | +2.2 days | +2.5 days |

| Laser Tek Response | |||

| Based on future projections (2015~2100) for Kaohsiung City, where the headquarters is located, under both 1.5℃ and 2℃ global warming scenarios, the annual precipitation change rate and the number of consecutive dry days per year in Kaohsiung will increase. Greater precipitation variability means more unstable rainfall, which may lead to more frequent droughts and heavy rain events. The company may face flooding at the plant or surrounding areas, or raw material supply shortages causing shipment delays, resulting in reduced orders and revenue. Drought and water shortages may also occur. Although the company only uses water for daily needs and can respond by building water storage facilities, customers are major water users. If industrial water is restricted due to shortages, customer operations will be affected, leading to a decrease in company orders. | |||

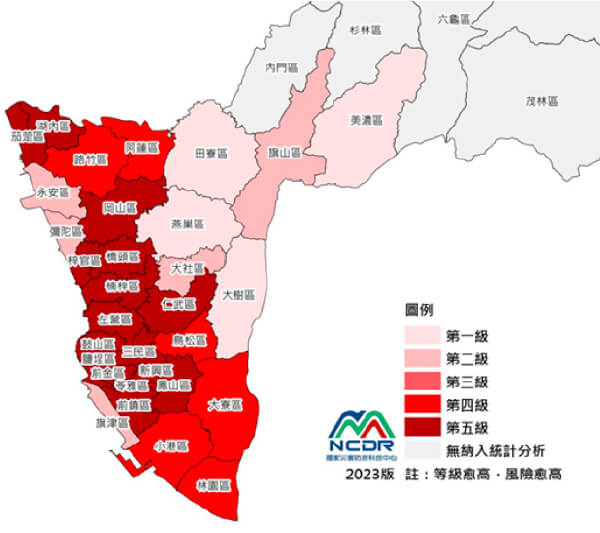

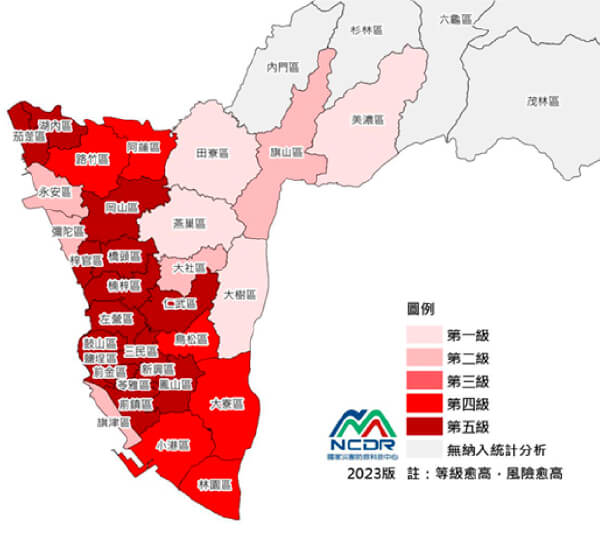

| Flood Disaster Risk | |

|---|---|

| 1.5°C Scenario (AR6 Mid-Century) | 2°C Scenario (AR6 Mid-Century) |

|

|

| Laser Tek's headquarters and main production sites are located in Qianzhen District, Kaohsiung City. Under both 1.5°C and 2°C scenarios, the area is classified as flood hazard level 5, indicating the 'relatively' highest disaster risk. The company must consider the adequacy and regular maintenance of drainage and flood control facilities. If the frequency of flooding events increases, relocation issues must be considered to avoid impacts on supply, employee commuting, and workplace safety. Constructing related facilities or relocating and building new plants will increase financial costs. | |

| Kaohsiung Sea Level Rise (Baseline 1995-2014) | |||||

|---|---|---|---|---|---|

| Scenario | 2040 | 2060 | 2080 | 2100 | |

| Global Warming Level (GWL) | 1.5℃ | 0.12 m | 0.21 m | 0.32 m | 0.43 m |

| 2℃ | 0.13 m | 0.25 m | 0.37 m | 0.51 m | |

| SSP Emission Scenario | SSP1-2.6 | 0.12 m | 0.22 m | 0.50 m | 0.41 m |

| SSP5-8.5 | 0.15 m | 0.30 m | 0.33 m | 0.78 m | |

| All scenarios are estimated values. Due to the complex submarine topography around Taiwan, there is high uncertainty. According to research by the National Science and Technology Center for Disaster Reduction, sea level rise will cause coastal water levels to rise and inundate low-lying areas, increasing the probability of flooding in coastal regions. The main affected areas are coastal lowlands, mostly wetlands, reclaimed land, or fish ponds. Tidal surges will also be affected. For example, in the Qijin area of Kaohsiung, after sea level rise, high tide overflow events exceeding the current seawall or port design standards are expected to occur more frequently. As Laser Tek is located in a coastal area, attention must be paid to coastal storm surge flooding. In addition to considering elevated infrastructure and waterproof gates, a plan should be developed to maintain supply stability during flooding. If the situation cannot be improved, relocation of the plant should be considered to maintain operations. | |||||

Transition Risk

| Scenario Name | Timeline | Assumptions | Results |

|---|---|---|---|

| IEA Net Zero Roadmap: A Global Pathway to Keep the 1.5°C Goal in Reach | 2030-2050 | Developing/Emerging economies (with net zero commitments) carbon pricing 90-200 USD/ton CO2e | According to ISO14064-1:2018, the total Scope 1 and Scope 2 greenhouse gas emissions of Laser Tek's Kaohsiung headquarters, Lin Guang Plant, and Hsinchu branch are about 1,500 metric tons CO2e/year. If no emission reduction plans or measures are implemented, and the company's total emissions are monetized, the company would need to bear approximately USD 135,000 to 300,000, significantly increasing operating costs. |

| Science Based Targets initiative (SBTi) | 2024-2034 | Minimum emission reduction calculated by linear reduction rate (about 4.2% per year) | Assuming the company's base year is 2024, with a target to reduce Scope 1 and Scope 2 emissions by 42% by 2034, if revenue and capacity remain unchanged, the company must purchase renewable energy in addition to optimizing existing processes to achieve the reduction target, resulting in an estimated expenditure of at least NT$790,000 to NT$1,080,000. |

Risk Management

Laser Tek has incorporated climate risk into its enterprise risk management process. Through risk management procedures, the company identifies potential climate risks and opportunities, formulates response measures, regularly reviews the effectiveness of implementation, and makes timely adjustments to align with overall trends and company policies.

Climate-Related Risk Management Process

Establish a climate-related risk management process in accordance with the Task Force on Climate-related Financial Disclosures (TCFD) framework. This includes collecting domestic and international information on climate risks and opportunities, referencing international reports and domestic data for climate scenario analysis, and providing the results to risk management department members for subsequent evaluation. Climate risk questionnaires are distributed to risk management department members for assessment. Based on the questionnaire, two indicators—'impact level (financial impact)' and 'likelihood (financial impact)'—are used as criteria to identify and rank risks, produce a risk matrix, and develop corresponding response measures. The results are reported to the board of directors and disclosed to stakeholders via the company website or the sustainability report.

Risk Scale Assessment and Risk Classification Criteria

Each issue is measured for impact level (financial impact) and likelihood (probability and trend of occurrence). The collected data is averaged, and the product of the average impact level (financial impact) and the average likelihood (probability and trend of occurrence) is calculated and ranked to understand the risks and opportunities faced by the company and to formulate relevant countermeasures to mitigate the impact of climate risks.

Risk exposure value = impact level (financial impact) × likelihood (probability and trend of occurrence)

Metrics and Targets

Since 2022, Laser Tek has adopted ISO 14064-1:2018 for greenhouse gas inventory to identify emission hotspots and facilitate the company's future carbon reduction plans. In 2022, only the Kaohsiung headquarters and Kaohsiung Lin Guang Plant were inventoried. The inventory boundary will continue to expand, with the Hsinchu branch included in 2024. By 2026, the company aims to complete GHG inventory and assurance for all Taiwan business sites, establish a GHG emission base year, promote subsequent reduction plans, and extend the parent company's operating model to consolidated subsidiaries. By 2028, Laser Tek will complete a GHG inventory consistent with the financial reporting boundary and obtain third-party verification from a qualified institution. In addition, the company targets a 40% reduction in GHG emissions by 2035. Currently, Laser Tek has not established an internal carbon pricing or incentive system. In the future, the company will first establish environmental accounting to facilitate the introduction of an internal carbon pricing system and link it to internal performance.

Laser Tek Greenhouse Gas Emissions

| Category/Scope | Category | 2022 | 2023 | 2023 |

|---|---|---|---|---|

| Category 1 (Scope 1) | Stationary Combustion | 0 | 0 | 0.2966 |

| Mobile Combustion | 13.7411 | 6.4479 | 6.1542 | |

| Process Emissions | 0 | 0 | 0 | |

| Fugitive Emissions | 2.0655 | 45.5361 | 75.1080 | |

| Category 1 (Scope 1) Subtotal | 15.8066 | 51.9840 | 81.5588 | |

| Category 2 (Scope 2) | Purchased Electricity | 1,496.2841 | 1,318.1065 | 1,309.8750 |

| Purchased Energy | 0 | 0 | 0 | |

| Category 2 (Scope 2) Subtotal | 1,496.2841 | 1,385.1662 | 1,309.8750 | |

| Category 1 (Scope 1) + Category 2 (Scope 2) Total | 1,512.0907 | 1,370.0905 | 1,391.4338 | |

| Category 3 to Category 6 (Scope 3) | Upstream Transportation | 67.8757 | ||

| Employee Commuting | 86.7265 | 79.1311 | 79.9538 | |

| Business Travel | 13.6851 | |||

| Purchased Goods | 263.7257 | 237.6915 | 246.2834 | |

| Waste Disposal | 5.3658 | 323.3551 | 7.7287 | |

| Category 3 to Category 6 (Scope 3) Subtotal | 355.8180 | 360.0077 | 415.5267 | |

| Category 1 to Category 6 (Scope 1+2+3) Total | 1,867.9087 | 1,779.3121 | 1,806.9605 | |

|

||||

Intellectual Property Management

Through the management of intellectual property, the company implements corporate governance to ensure the company's sustainable operation, and formulates “Intellectual Property Management Measures”, which are managed and maintained by the management department to prevent infringement of patents, trademark rights and trade secrets or the possibility of litigation.From time to time, the company employees participate in courses related to intellectual property and invites legal units to the company to promote and establish employees' correct concepts, and implements the protection and management of intellectual property and prevents important trade secrets from leaking, so as to enhance the company's industrial competitiveness and company operations develop.

Trade Secret Protection

| Item | Content |

|---|---|

| Access Control | All company employees are issued access cards with permissions assigned according to department attributes; non-employees must register their identity when visiting and be accompanied by a company employee at all times. |

| Information Security Management | All company computer equipment requires login with an employee's personal account and password, which must be changed regularly. |

| Department-Specific Space | The company allocates dedicated file storage space for each department, which is independently planned and used by each department; physical spaces must be properly secured with keys. |

| Confidentiality Awareness Promotion and Training | New employees sign confidentiality agreements to ensure awareness of trade secrets and establish risk awareness in advance. Legal department colleagues are arranged to participate in relevant courses, with a total of 2 sessions this year, including information security and trade secret protection, intellectual property, and other courses. |

| item | content |

|---|---|

| Patent application | Fully know the development of industry trends and then apply for patents in response to market development trends. |

| Patent Layout Establishment | Based on the product orientation, examine the patents involved in the relevant technologies to understand the current status of the industry. |

| Periodic Maintenance Review | Examine the use of certified patents and their relevance to products to assess the need for continued maintenance. |

| Patent R&D Conference | Before each patent proposal proceeds to the official application process, discuss and communicate with multiple parties, including search, element review, preliminary review suggestion, final decision, etc., so as to effectively check the quality of the patent. |

| Patent Course & Information Sharing | Provide external courses to enhance the sensitivity of R&D personnel to the legal boundaries of patent applications. |

Laser Tek Patent Achievements in the Past 3 Years

| Year | 2021 | 2022 | 2023 |

|---|---|---|---|

| Patent Item | Taiwan | Mainland China | Mainland China |

|

Rapid optical path architecture for cutting Low-K wafer (Invention). | Laser rapid drilling device (Invention). | |

| Mainland China | |||

|

|||

| Note: If it is an invention patent, it is indicated in parentheses; otherwise, it is a utility model patent. | |||

Laser Tek Patent Achievements in the Past 3 Years

| Region | Patent | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Taiwan | Utility Model | 2 | 0 | 0 |

| Invention Patent | 2 | 0 | 0 | |

| Mainland China | Utility Model | 1 | 0 | 0 |

| Invention Patent | 3 | 1 | 1 | |

| United States | Utility Model | 0 | 0 | 0 |

| Invention Patent | 0 | 0 | 0 | |

| Total | 8 | 1 | 1 | |

Laser Tek Cumulative Valid Patents in the Past 3 Years

| Region | Patent | 2022 | 2023 | 2024 |

|---|---|---|---|---|

| Taiwan | Utility Model | 9 | 9 | 8 |

| Invention Patent | 9 | 9 | 9 | |

| Mainland China | Utility Model | 7 | 7 | 7 |

| Invention Patent | 3 | 4 | 5 | |

| United States | Utility Model | 0 | 0 | 0 |

| Invention Patent | 1 | 1 | 1 | |

| Total | 29 | 30 | 30 | |